Mercury Systems

Key programs include Aegis, Patriot, Surface Electronic Warfare Improvement Program ("SEWIP"), Gorgon Stare, Predator, F-35 and Reaper.

Headquartered in Andover, MA, and with manufacturing and design facilities around the world, Mercury specializes in engineering, adapting and manufacturing new solutions purpose-built to meet the industryвҖҷs current and emerging high-tech needs. Our employees are committed to Innovation That MattersВ®.

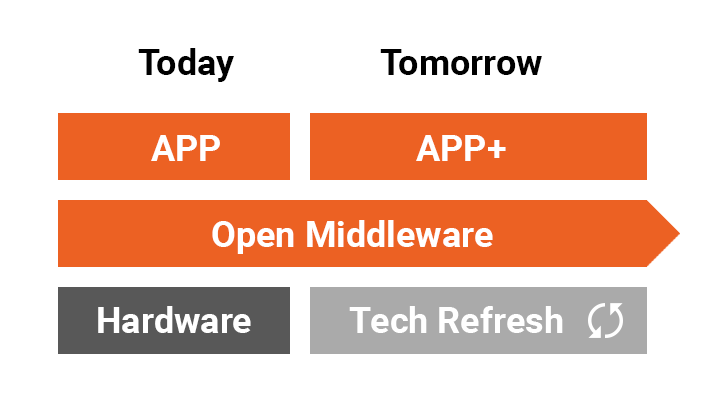

We are at the intersection of high-tech and aerospace/defense and therefore have the responsibility to lead from the front. We achieve this with an innovative business model that combines the power and speed of an R&D-centric high-tech company with the trust and security of an aerospace and defense-focused business.

Sensor Signal Processing

Mercury champion OSAs that support customersвҖҷ need for affordability and interoperability while infusing innovation into every compute element we build. Our portfolio of embedded VME, OpenVPX and AdvancedTCA building blocks for integration into pre-tuned processing subsystems are ideally suitable for embedded industrial, aviation and defense applications.

Mercury ruggedly package the latest CPU, GPU and FPGA processors and keep them cool with the best technologies in the industry. Our miniaturizing wafer-stacking and system-in-package fabrication techniques drive the greatest SWaP performance and memory densities. Many of our embedded sensor processing solutions support built-in MOTS+ and BuiltSECURE technologies for extreme ruggedness and nation-state-level security features. Mercury embedded sensor processing solutions are designed, made, coded and supported in the USA from trusted DMEA facilities.

BuiltSECURE

Embedded SSE for FMS

DMEA facilities

Managed supply chain for trus

MOTS+ Technology

Extreme environmental protection

Interoperable Processors

Scalable Xeon, GPU, FPGA for compute power

Scalable Across OSAs

OpenVPX, AdvancedTCA & ATX

Mission Computing & Avionics

Mercury Systems latest rugged safety certifiable building blocks have backwards compatibility and are designed with a top-down approach for interoperability and ease of pre-integration.

Highest Design Assurance Level (DAL-A) for both DO-178 software and DO-254 hardware

30+ years designing/manufacturing deterministic processing solutions for safety certification

EASA, FAA, JAA, and Transport Canada safety certification experience lowers program risk

More I/O interfaces, including safety certifiable Ethernet and MIL STD 1553 data bus

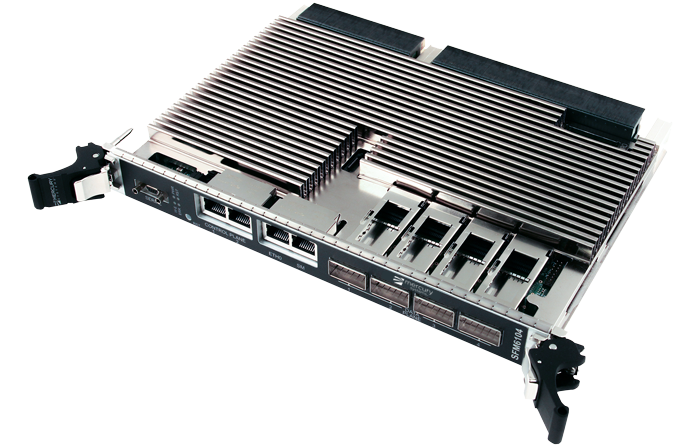

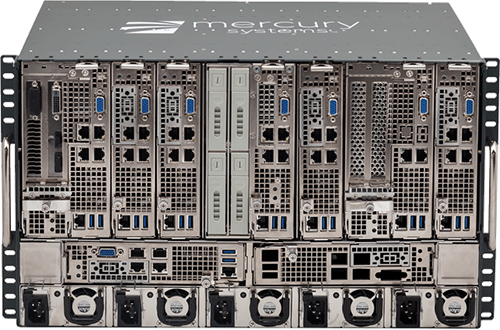

Rugged Rackmount Server

COTS Technology

Quick and affordable adoption of leading commercial technologies

Enhanced Reliability

Proven performance & availability in stringent environments.

Size, Weight & Power (SWaP)

To meet systems engineering constraints at the edge.

Interoperability

Seamless integration across multiple platforms.

Security

With вҖңbuilt-inвҖқ not вҖңbolted-onвҖқ secure solutions.

Modular Composability

Built-in composability for a more cost effective purchase.

Simple Logistics/Upgrades

Relieve the challenges and costs associated with logistics and upgrades.